*Press Play Below to Begin Audio*

Source of Images: OSHA

Fall Hazard Controls

Hierarchy of Fall Hazard Control:

1. First line of defense

- Eliminate the fall hazard

2. Second line of defense

- Prevent the fall

3. Third and last resort

- Control the fall

Eliminate Fall Hazards

Work From the Ground

- Gauge at top of tank moved to ground level

- Use drone, equipped with camera, for inspections at heights

Hole Covers/Grates

- Covering floor openings is a very effective way to eliminate a fall hazard, especially if access to the hole is rarely necessary.

- When routine travel over the opening is necessary, often a cover is used, such as a trap-door. Covers must be designed to withstand the potential load that may be placed upon them. For example a 36”x 36” floor-hole cover that will only experience foot traffic would be much different than one experiencing fork truck traffic.

- They must also be secured (bolted, hinged, latched, locked) to prevent accidental displacement as well.

- It should be noted that the employer should communicate who is authorized to open and/or remove the cover and that when the cover is opened or removed another means of protection is necessary. When the floor opening cover is opened, either a temporary guardrail must be in place or the opening must be constantly attended by someone until closed.

Prevent the Fall

Guardrails

- Guardrail systems are vertical barriers consisting of top rails, mid-rails, and intermediate vertical members. Guardrail systems can also be combined with toe-boards, which are barriers that prevent materials and equipment from dropping to lower levels.

Source of Images: OSHA

Fences and Barricades

- Prevents unauthorized employee exposure to fall hazard

- Employer authorizes access

- Authorized personnel must then be protected from the fall hazards within

Fences, barricades, and locked doors, whether inside the facility or outside, can be used to prevent unauthorized access to areas where a fall hazard exists. Only authorized and trained employees would have access. Once inside, a method of fall protection must be implemented for the authorized worker.

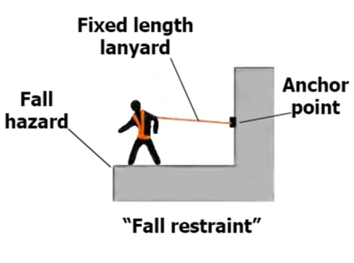

Personal Fall Restraint

Prevent falls by keeping worker from reaching fall hazard

Comprised of a body belt or body harness, an anchorage, connectors

Often used when section of guardrail or hole cover is temporarily removed

Fall restraint systems prevent falls by keeping the worker from reaching a fall hazard. While fall restraint systems are not mentioned in OSHA’s fall protection rules, OSHA will accept a properly used fall restraint system in place of a personal fall arrest system when the restraint system is rigged so that the worker cannot get to the fall hazard. In effect, (if properly used) the system tethers a worker in a manner that will not allow a fall of any distance. A fall restraint system is comprised of a body belt or body harness, an anchorage, connectors, and other necessary equipment. Other components typically include a lanyard, and may also include a lifeline and other devices. Note: A self-retracting lanyard is not appropriate for a fall restraint system unless the worker cannot reach the fall hazard when the lanyard is fully extended.

Source of Images: OSHA